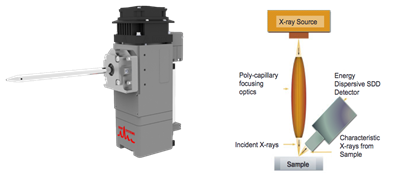

X-ray micro-fluorescence (μ-XRF, or micro-XRF) is an analysis technique that conforms to the principles of X-ray fluorescence (XRF). The difference lies in the fact that the µ-XRF have a µm spatial resolution level, while XRF work at the mm level. A specialized polycapillary optic is used to reduce the X-Ray beam spot size at the µm order.

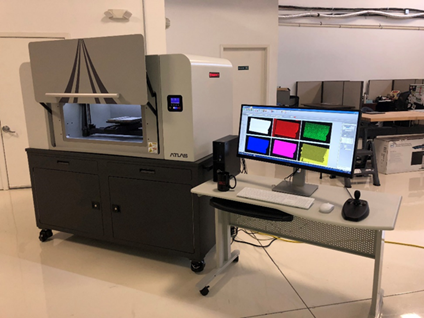

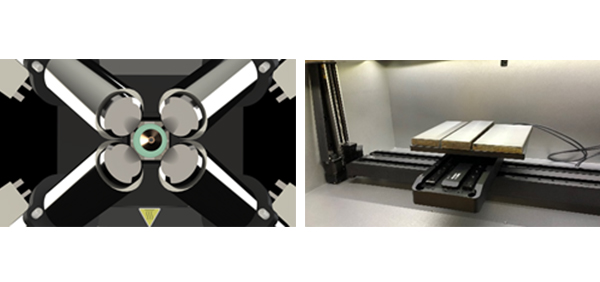

The sample is placed on a motorized stage, allowing movements and scanning. This allow to scan a sample and create an X-ray image associated with the localized elemental sample composition for each sample position (elemental mapping), at the µm level.

Archeology/Museums, Museum artifacts and currency, Forensics science, Metals and alloys, Gemstone inclusions, Painting authenticity/dating, Paints, inks, pigments, Corrosion products, Paints, Biomedical devices/implants, Solar cells, Optical filters, Manufacturing, Pathology, Pharmaceuticals, Semiconductor, RoHS, WEEE, and ELV compliance, Environmental analysis, Lead contamination in consumer goods, Packaging, Soil contamination, Material characterization for recycling, Marine/ocean sediments, Airborne particles/air filters, Slurry, Forensic Science, Glass Chips, Paint cross sections, Metals/alloys, Inks/pigments, Soils/stones, Gunshot residue, Material identification, Geological, Meteorites, Phase boundaries, Mineral identification, Mining test cores, Metals and alloys, Electronics ,Glasses ,Building materials (concrete, cement), Packaging ,Medicine/Biology ,Bones/tissue, Leaves/plants, Pharmaceuticals, Implants, Particle Analysis,…

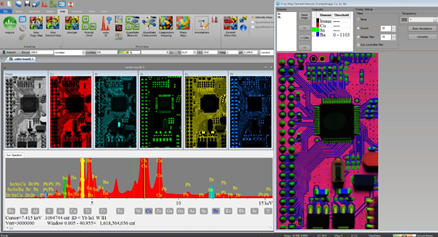

- Spatial elemental data

- Similar type data to SEM/EDS – elemental

- Point analysis

- Mapping

- Linescans

- No high magnification imaging, but do get x-ray image from map